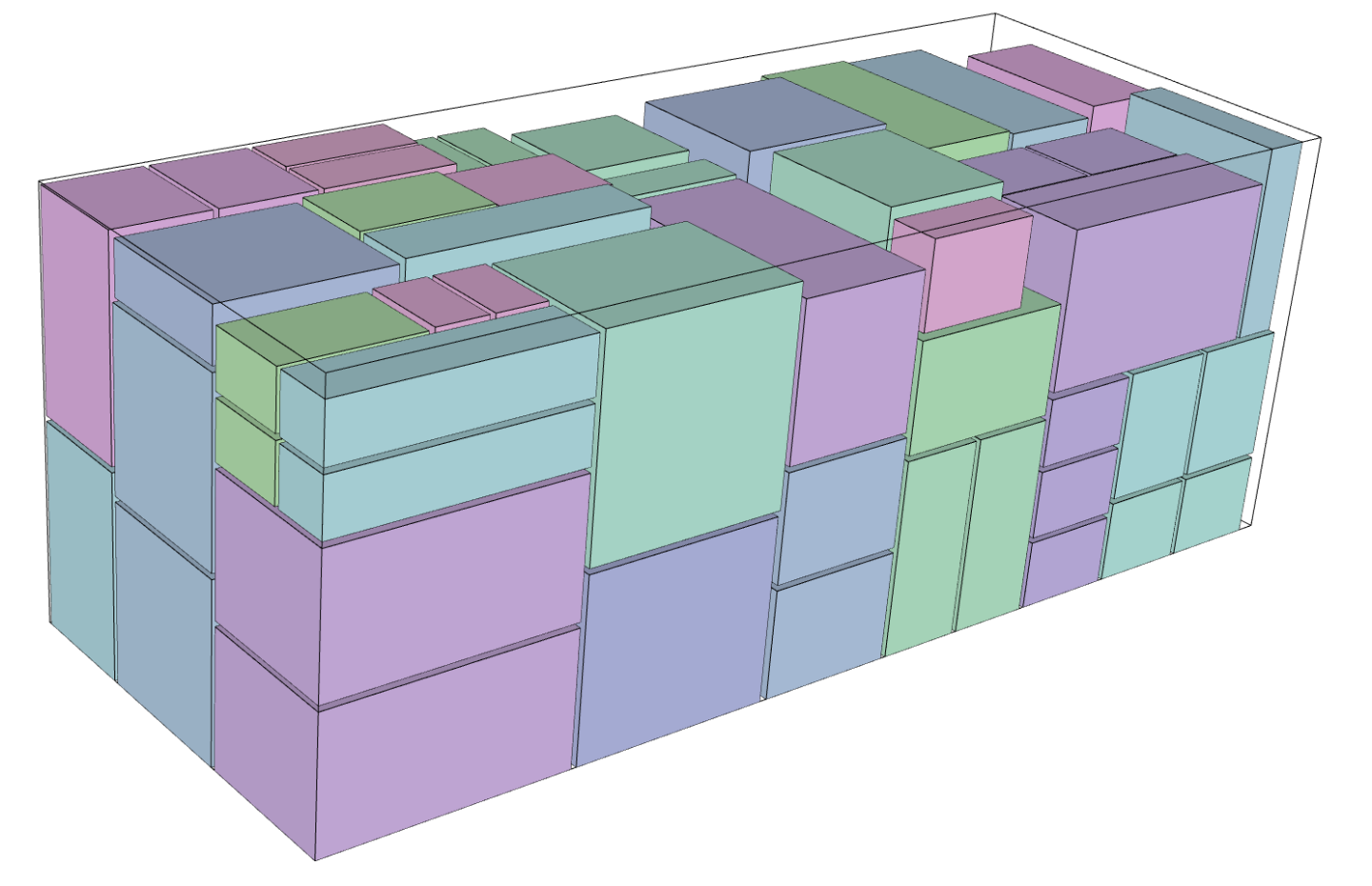

CuboNester-C generates cutting plans that can be obtained by straight, continuous (guillotine) cuts from end to end. This corresponds to the possibilities of common sawing technologies.

Benefits & Features

- The CuboNester-C shown here is designed for cutting blocks of material and can be used for metal, marble, graphite or foam, among other materials.

- CuboNester-P addresses packing, for example furniture parts into packages. Here you can find information about CuboNester-P.

Reusable remnants available in the warehouse or newly created during production can be included and evaluated in the optimization within the CuboNester-C software. By means of adjustable parameters, CuboNester-C can specifically prefer remnants over new input material, avoid the generation of new remnants as far as possible, and weigh these goals against the material utilization rate.

- Detected defects in the material can be bypassed during production.

- Cuts close to the edge (“dust cuts”) can optionally be avoided.

Use of the software

CuboNester is sold as a pure optimization engine and is intended for integration into other applications, such as plant control systems, MES or ERP systems. For this purpose, CuboNester has an XML interface that can be accessed via standard input / output, via a file interface or as a server service. The software runs on all current Microsoft Windows operating systems.

CuboNester is aimed at providers of software solutions who want to integrate optimization into their application, as well as larger companies that are willing to program or have programmed an appropriate connection to their IT systems.

To enable companies to get an impression of the software’s performance before programming a connection, Fraunhofer SCAI offers a demo user interface. This simple interface is not suitable for daily productive use. Please contact us for this purpose.