ModelCompare is a plug-in for pre- and post-processing finite element analysis (FEA) tools. It compares two similarly discretized FE models and presents their differences in geometry (mesh), material ID and sheet thickness.

ModelCompare identifies the differences between models based on the geometry defined by the discretization grid. It uses special imaging techniques that result in extremely short run times.

- Seamless interface as a plug-in

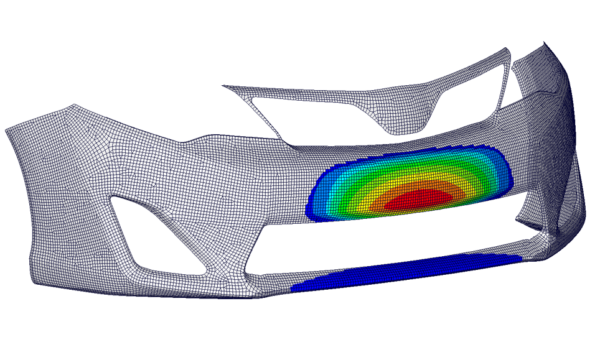

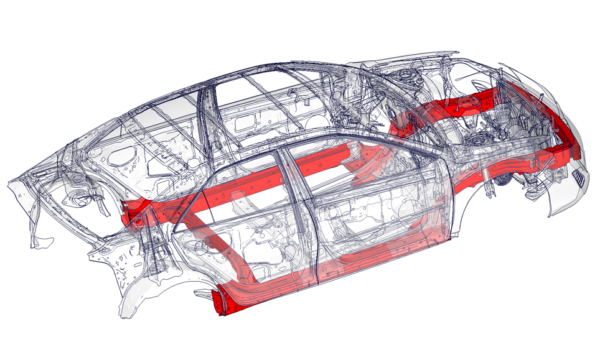

- Geometry changes

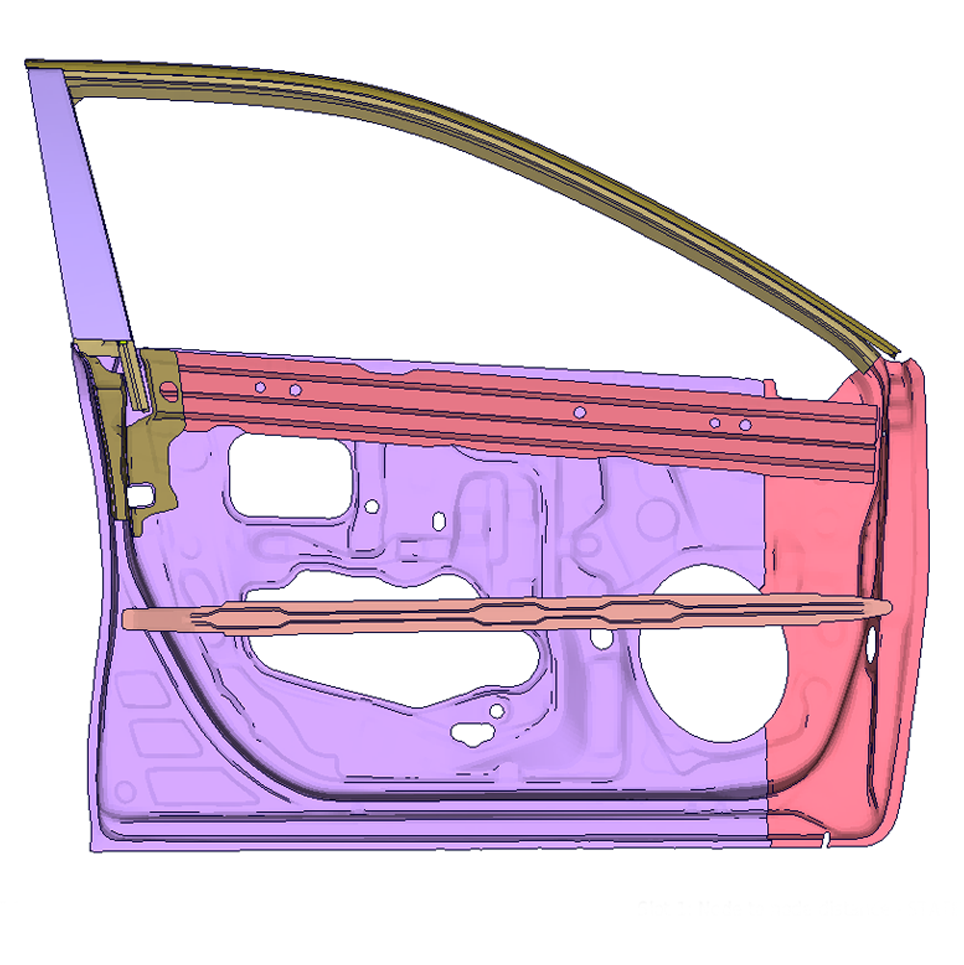

- Multi-part detection

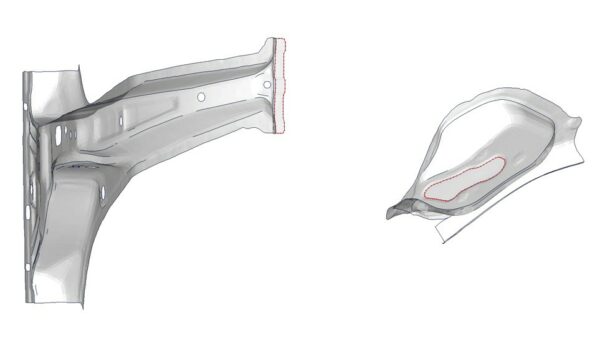

- Detection of material ID and thickness changes

- Detection of spot weld and RBE changes

Application areas

Any organization involved in computer-aided engineering (CAE) must deal with numerous designs that vary in geometry, materials, and constraints. ModelCompare is a quick-look tool capable of determining the differences between two FE models discretized in a similar way. ModelCompare lets you quickly compare two FE models in your preferred visualization tool without having to manually determine the differences. A report can be generated to document the changes.