On the way to automatic event detection for crash simulations

Benefits & Features

- Seamless interface as a plug-in

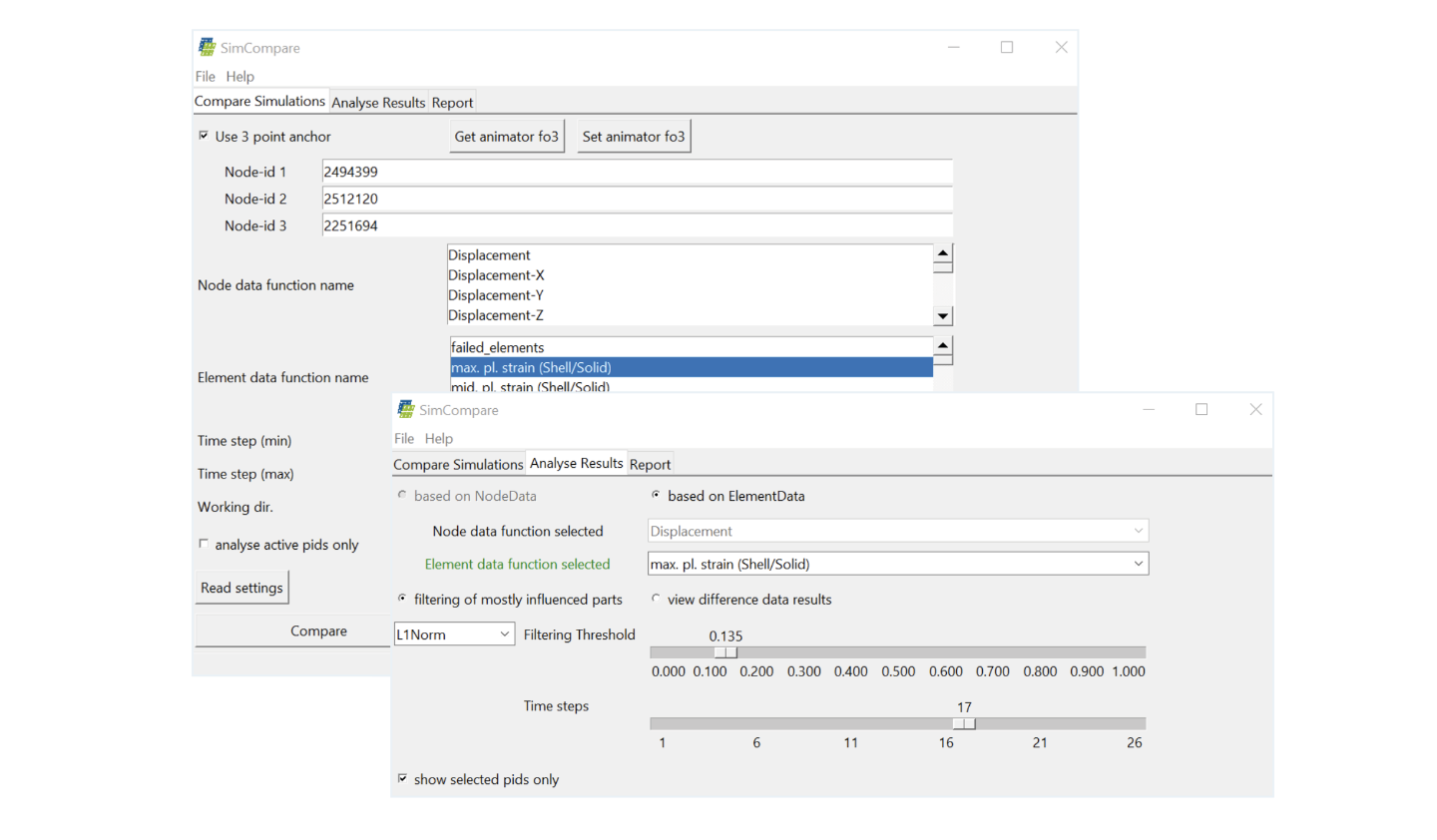

- Comparison based on functions for node and element data

- Determination of strongly influenced components

- Several comparison measures

- Visualization of local results

- Automatic report generation and storage of results

Context & Functionality

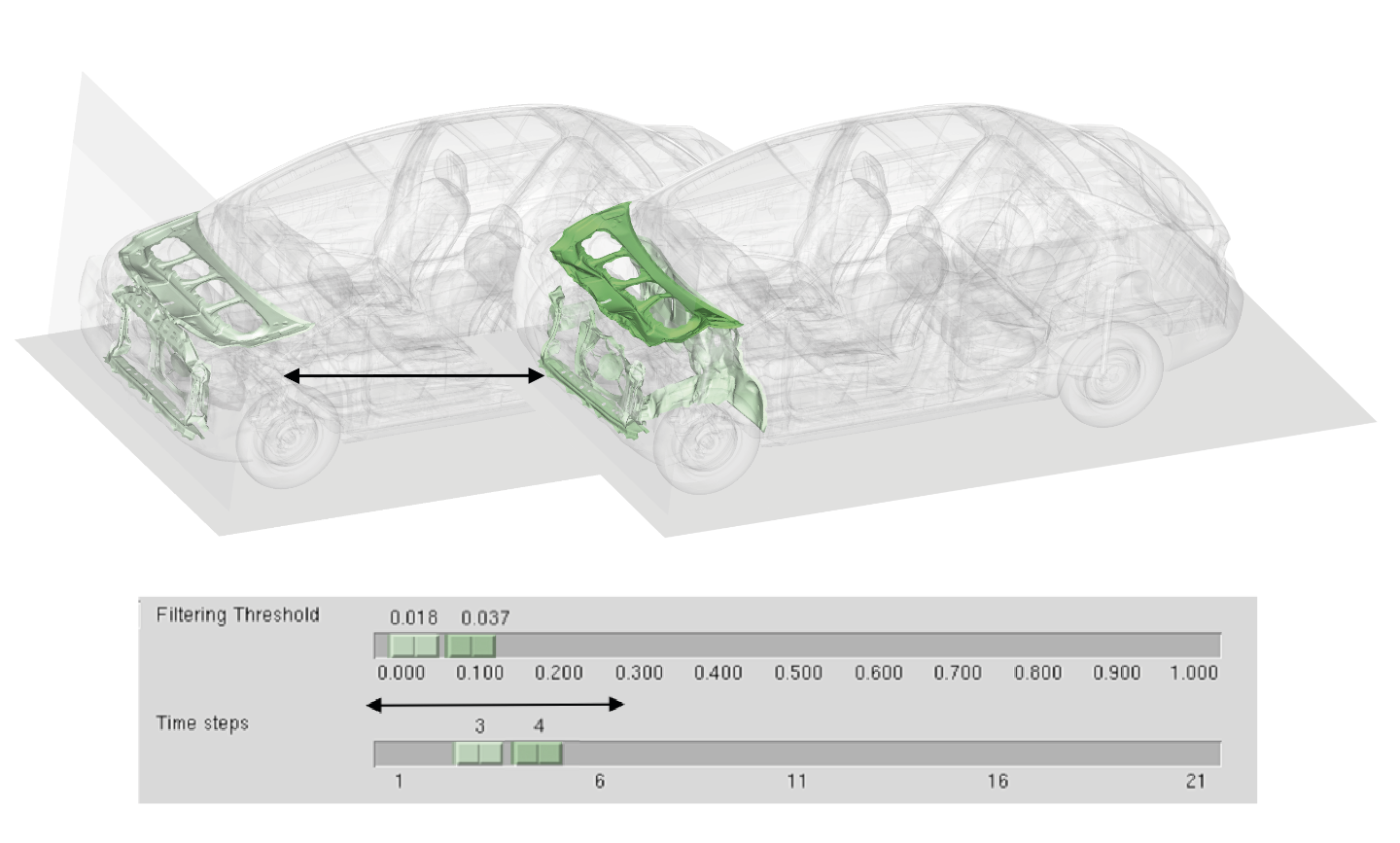

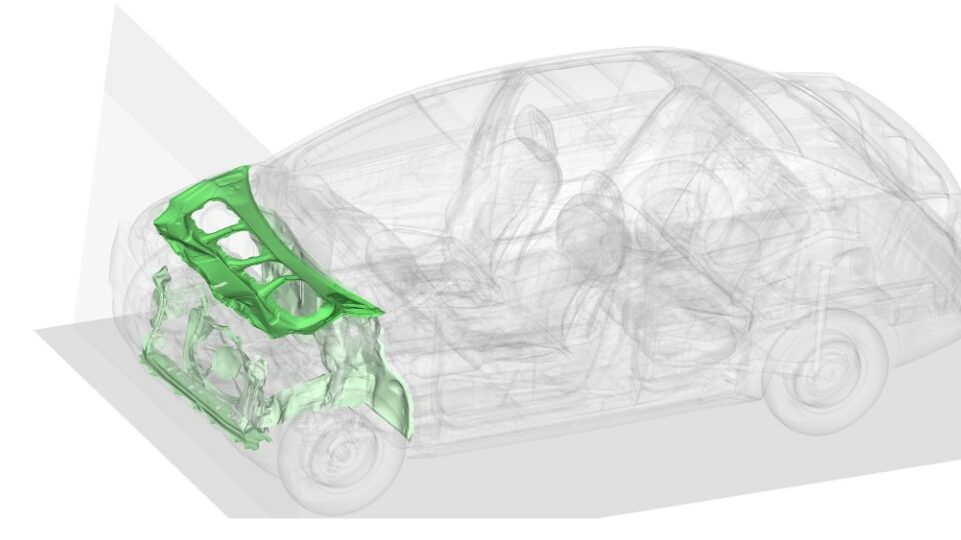

In computer-aided engineering (CAE), numerous design changes occur throughout the design development process until the final model meets all design criteria. Each of these design changes must be analyzed and their influences on the simulation results compared and evaluated. SimCompare is a tool for easy analysis of the effects of design changes in relation to data functions.

SimCompare automatically highlights relevant components over time along with local hotspots related to design changes. In this way, users gain insight into the effects of design changes, starting with just two simulations. In particular, it is no longer necessary to set up a simulation database. Manual determination of the differences is no longer necessary. To document the impact of design changes, the software generates a report that is automatically customized for each analysis run.

More advantages & features

Several comparison measures

Several measures of comparison (metrics) are available to focus on global or local influences. These can be extended to other engineering-based metrics, including expert knowledge, if desired.

Seamless interface as a plug-in

SimCompare is available as a plug-in for GNS Animator or as a stand-alone batch tool. The results are visualized directly in Animator. Thus, no additional tool is needed for CAE and SimCompare analysis can be easily integrated into an established analysis workflow.

Automatic event detection

The developers of SimCompare at Fraunhofer SCAI combine mathematics and machine learning to integrate existing application knowledge into data analysis methods. Thus, SimCompare represents an important step towards automatic event detection in an overall simulation data analysis workflow. The tool allows to systematically analyze a design tree and detect deviations caused by design changes. SimCompare can be used hand in hand with SCAI’s ModelCompare software to identify design actions realized through model fitting.