CutPlanner is a software package for automatic production planning (“Cut Order Planning”) in the textile processing industry.

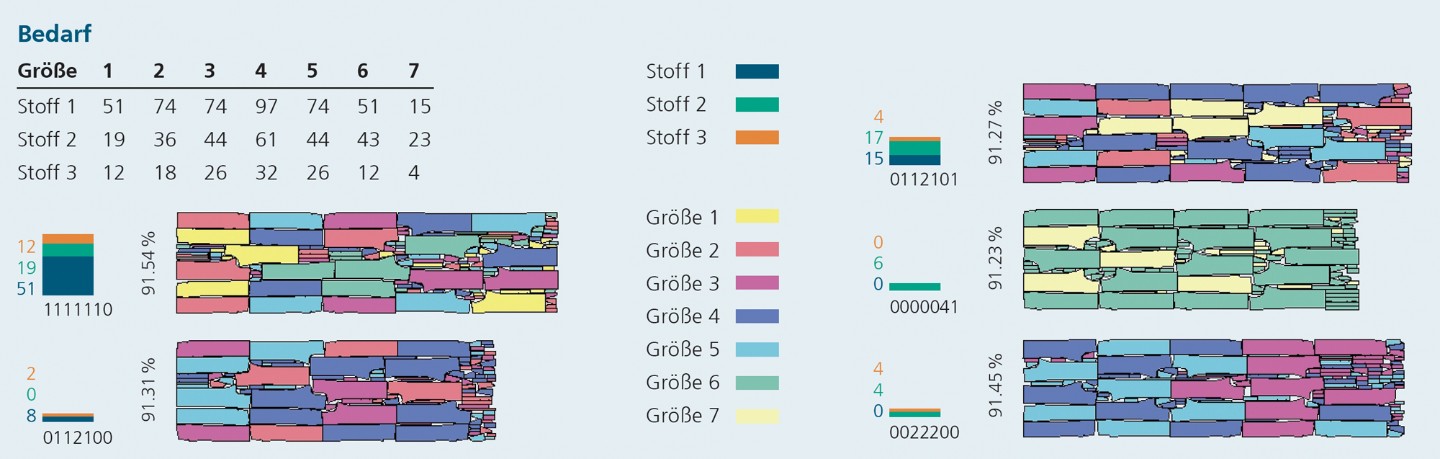

Solution by calculation of material costs, material utilization 91.44 %, calculation time: 30 minutes

CutPlanner can determine material costs in two different ways:

- Estimate of the cost of materials:

Estimated values for the loadings of markers – depending on the number of sizes on the marker – are used. - Calculation of the cost of materials:

CutPlanner uses software for the automatic creation of markers. In this way, the real material consumption can be determined.

Benefit & value

Starting from a customer order for a garment in different sizes and fabrics, CutPlanner creates a “cut plan”, a set of sizes on cutting patterns, with minimal cost. For each of these layplans, the number of layers necessary to meet the required order quantity is calculated.

The goal of CutPlanner is to minimize overall costs. These consist of costs for the fabric used (material costs) and various production costs incurred in creating the cutting patterns, preparing the cutting process and picking up the cut parts.

Methods

CutPlanner combines the latest optimization techniques to achieve the best results in the shortest time. Linear programming methods tailored to particularly large problems are used, adapted to the problem structure of “Cut Order Planning”.

Fast local search algorithms, pattern recognition methods and efficient heuristics support this approach. All of the above methods use dynamic parameter settings.

Integration into existing software

CutPlanner is aimed at developers of CAD and ERP systems in the textile processing industry. The software package is organized as a library (DLL) and can be easily integrated by developers into their own software and GUIs.

CutPlanner should be installed on a fast PC with at least 1 GB RAM. The software runs on Windows operating systems, other operating systems can be supported on request.