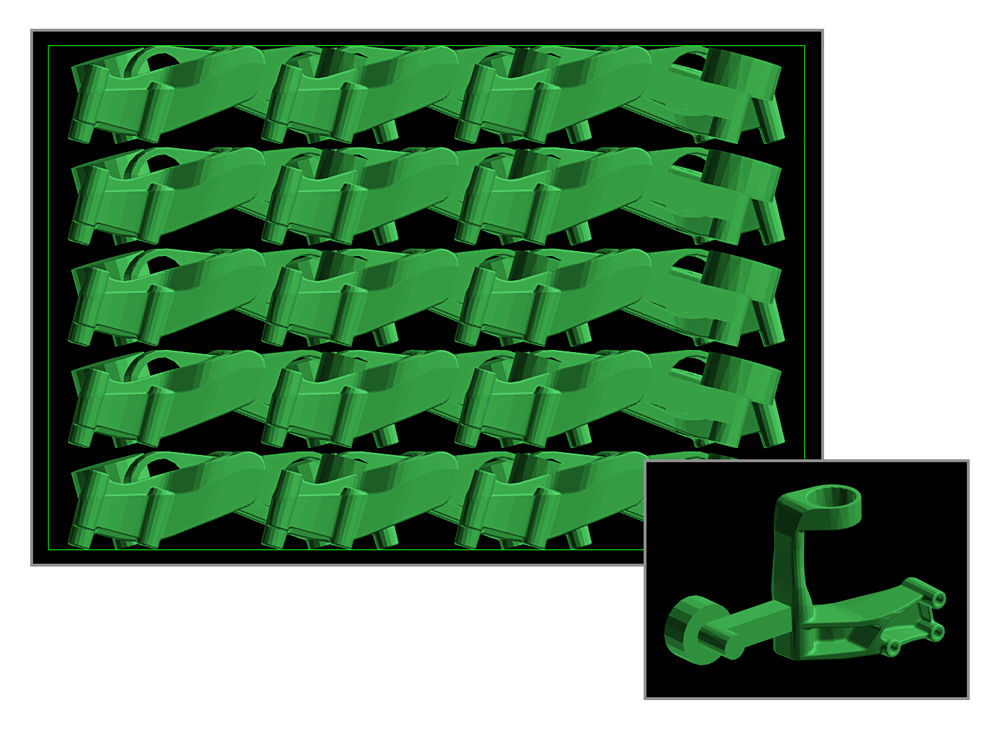

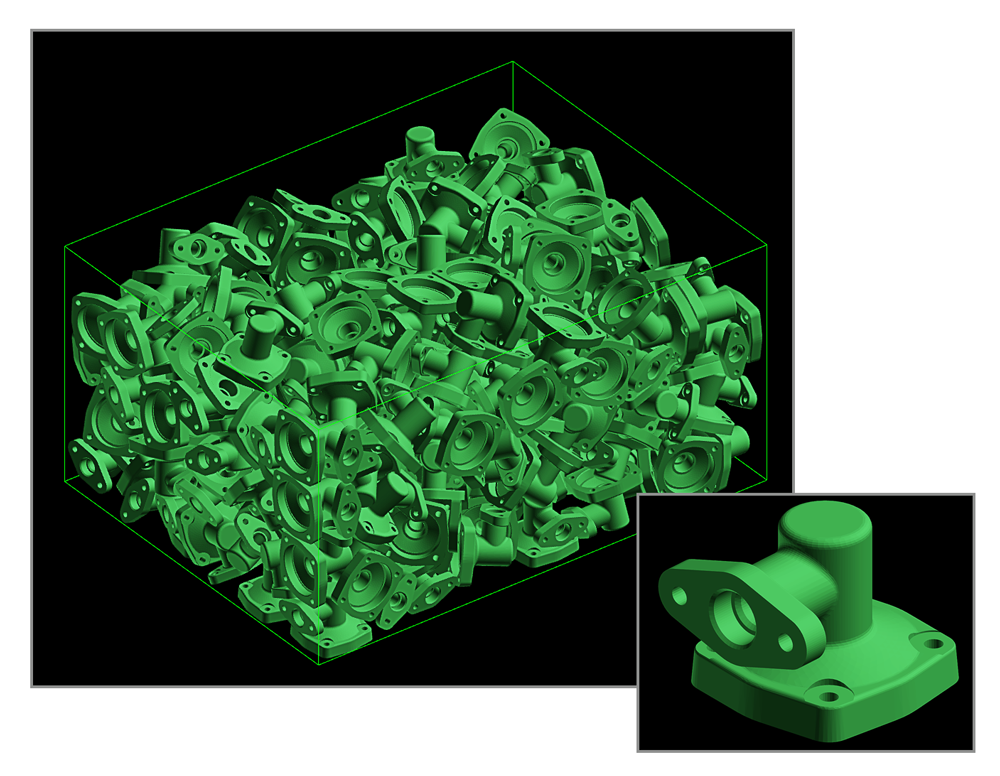

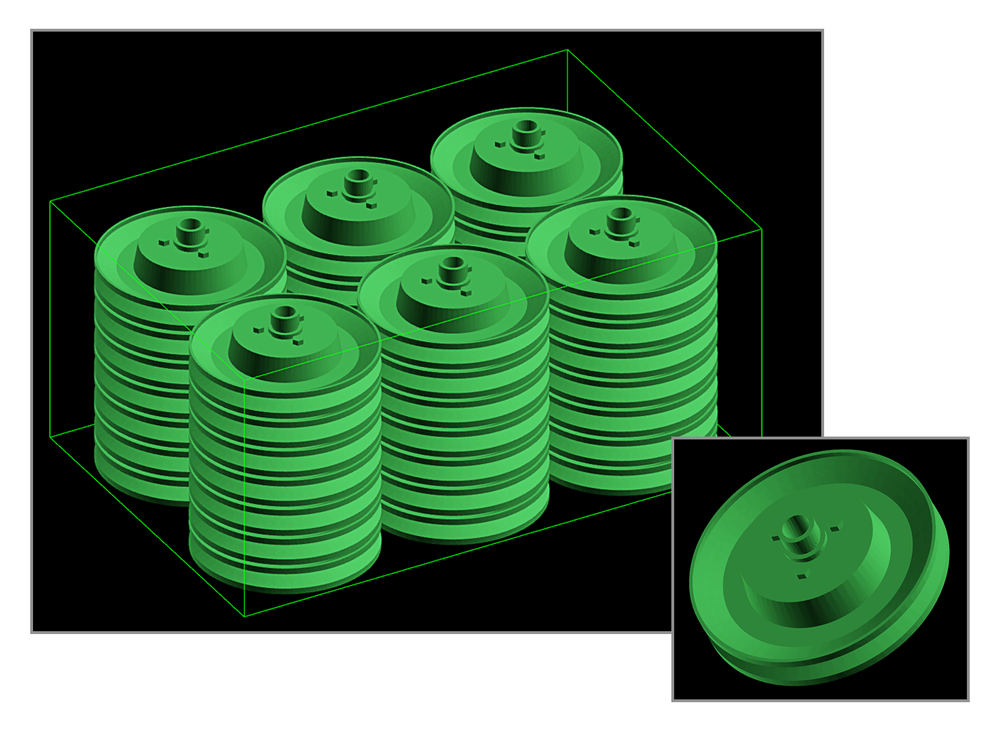

PackAssistant supports the planning of container filling with identical parts using 3D data sets (CAD). By taking the component geometries fully into account, even complex parts can be packaged in such a way that they take up as little space as possible.

PackAssistant saves time and reduces costs through

- Optimized container utilization

- the elimination of time-consuming packing attempts

- early transport, container and storage planning

- a significant support in the preparation of the offer

Benefit & value

Optimal container filling saves time and money when it comes to transportation and storage capacity. That’s why experienced packaging planners sometimes fiddle around for a long time when packaging components with complex geometries – and still often achieve lower packing densities than the PackAssistant software.

PackAssistant greatly facilitates the packaging planning of components in the industry. The automated calculation of the best possible packaging on the computer makes fast, cost-effective and optimized container and logistics planning possible.

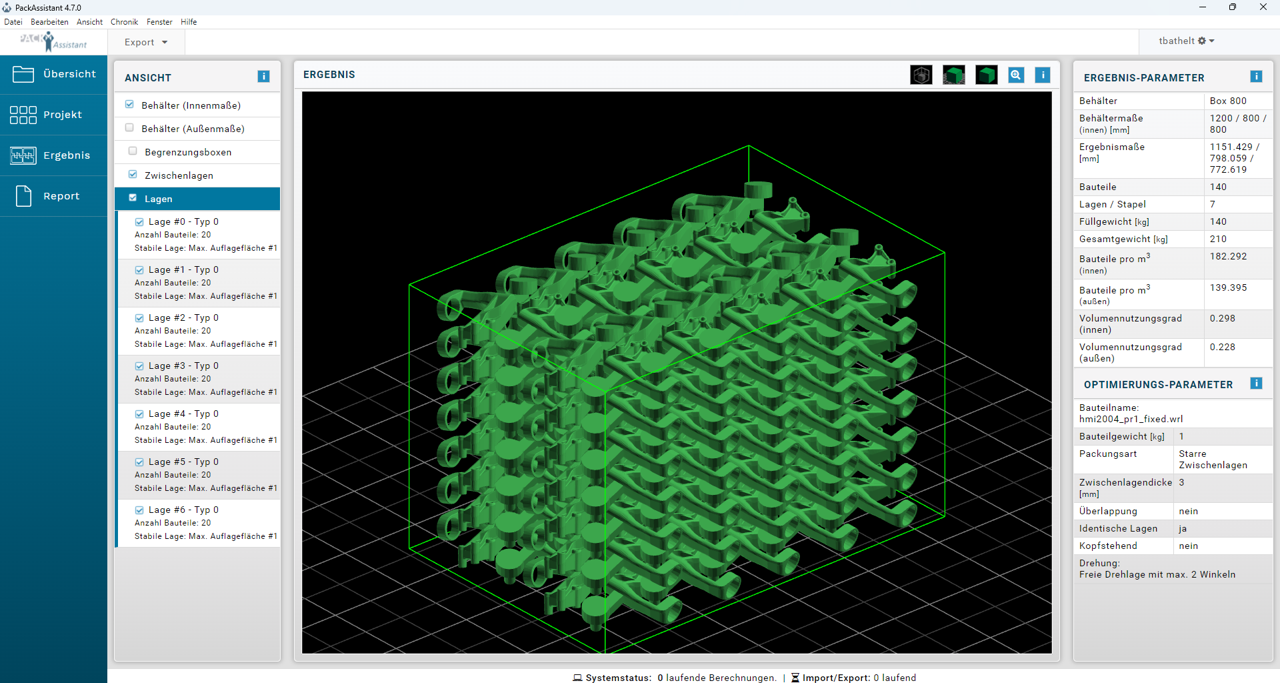

PackAssistant – User Interface

Introduction to user interface and operation

Functions / Packing types

Packaging instruction and 3D CAD output

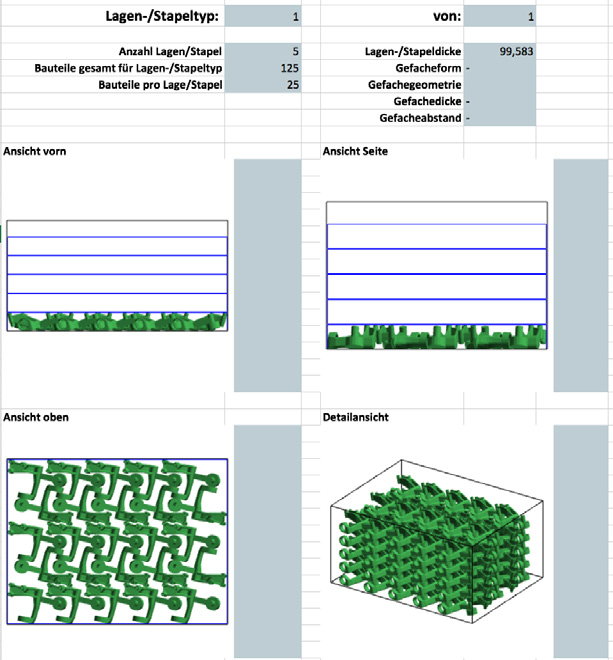

PackAssistant provides the planner with meaningful 3D images as packaging instructions, thus creating an ideal basis for the creation of individual quotations. The customer receives a complete representation of his future components in the planned packaging structure. Until now, such visualized results were only possible through elaborate drawings or graphics.

The packing instructions can be output as a Microsoft Excel or Word document. The packaging instructions templates can be customized to meet the requirements of each company.

In addition, the results can be output as CAD data sets in the formats JT (*.jt), STEP (*.stp, *.step) and VRML (*.wrl). This enables an even more vivid presentation of the optimization results, which can be attached to the packaging instruction if required. With 3D viewer software, sections and views of the packing result can be generated in the process.

Examples packing instructions

- 3D display / 3D result display

- 4-window view, as familiar from CAD applications.

- The packing direction is visualized by a bottom grid or an open container.

- Live adjustment of the bounding box and maximum bearing surface for easy manual creation of stable layers.

- Rotation works easily and no parts are hidden.

- Easily show and hide individual layers in the result.

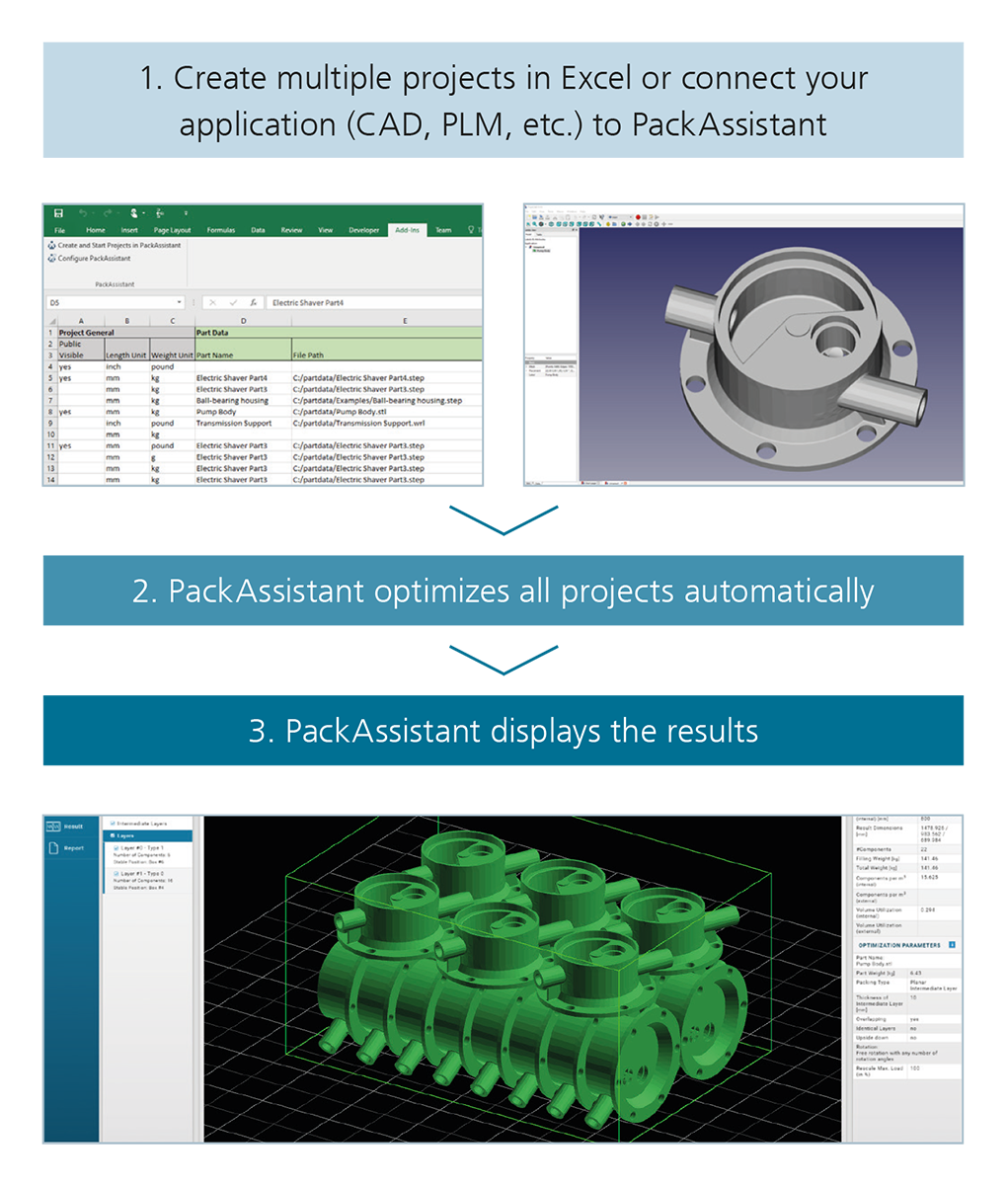

Add-on module for PackAssistant automation

PackAssistant accepts data from other programs via a new interface so that projects can be created and their optimizations started in an automated manner. This facilitates a more effective integration into the company‘s business processes and results in a faster workflow. The creation and optimization of projects via the automation interface takes place without user interaction or additional waiting times. Furthermore, there is no limitation on the number of projects that can be created and optimized via the add-on module.

The add-on module can be used in two ways:

- Excel Add-In:

Part of the add-on module is an Excel add-in. This allows projects created in Excel to be sent to PackAssistant and to have the optimizations started. - Direct use of the interface:

The add-on module uses a standardized and widely used text format (JSON) for data exchange between PackAssistant and other software applications employed in the company. The standardized exchange format makes it possible to connect all software applications to PackAssistant that allow external programs to be called. The corresponding application must be configured accordingly and, if necessary, extended by an interface connection. The Excel Add-In is an example of such a connection to the interface.

You can find more information in the product sheet.