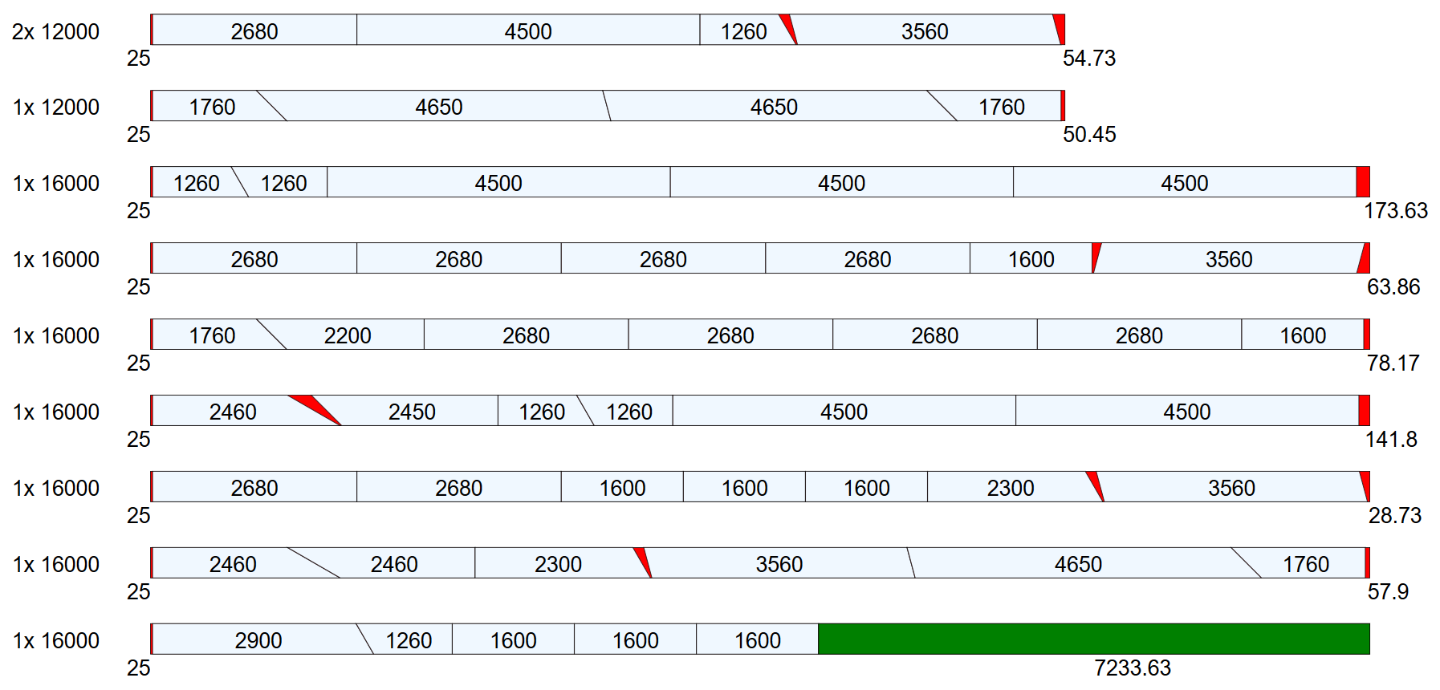

The AutoBarSizer software determines optimized cutting layouts for cutting steel profiles and other bar material (long material) into shorter parts (fixed dimensions). The generated solutions are characterized by a high degree of material utilization (yield), cutting losses are minimized.

Optimize miter cuts in seconds

When layouts with miter cuts are created, AutoBarSizer also optimizes the nesting (interlocking) of the parts. For this purpose, it is sometimes useful to rotate the parts. Which rotations are permitted can be specified by the planner depending on the symmetries of the material and production requirements.

AutoBarSizer solves problems that arise during planning in rolling mills and at steel distributors, but also in the wood processing industry as well as at manufacturers and processors of all types of material-strips. The calculations for a usual size cutting layout take only a few seconds to a few minutes at most.

Benefit & value

The computer based optimization of length combinations for cutting bars and rods leads to the best possible avoidance of waste and can thus save considerable amounts of expensive material. Resources are saved and production costs are decreased without affecting the quality of product or service.

By individual assessment of remnant usage and remnant production, AutoBarSizer allows the user to better manage the stock and avoid unnecessary storage costs for remnants.

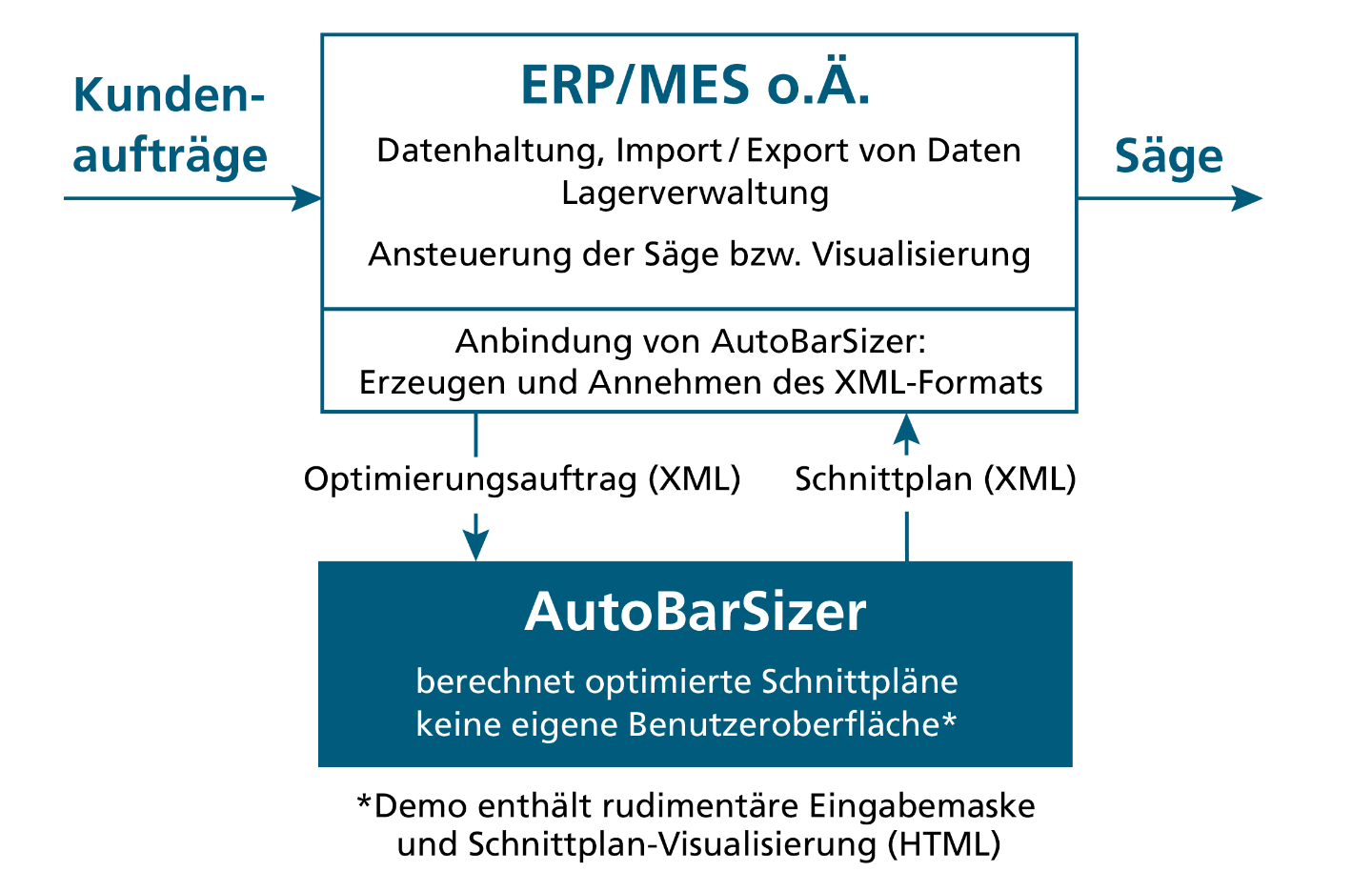

Integration into existing software

AutoPanelSizer is distributed as a pure geometric optimization engine and is intended for integration into other applications, for example plant control systems, MES or ERP systems. For this purpose, AutoPanelSizer has an XML interface that can be accessed via standard input / output, via a file interface or as a server service. The software runs on all current Microsoft Windows operating systems.

Target groups

Providers of software solutions who would like to integrate optimization into their application, as well as larger companies who are willing to program or have programmed a corresponding interface to their IT systems.

To give you an impression of the performance of our software before you integrate it into your systems, we offer a demo GUI. This simple GUI is not suitable for daily productive use.

Features of AutoBarSizer

Miter cut

Parts and material

Machine

Optimization

Remnants and waste

Advantages